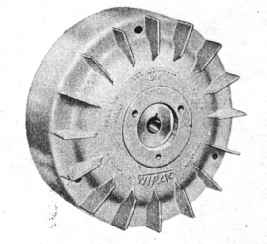

Series 90 Flywheel with Fins

3. Check contact breaker points for correct gap setting

and see that the breaker arm is free to move. See that

the breaker points are clean. If burnt and badly

pitted this will indicate a faulty condenser (renew), or

magneto run with dirt between the points. (Renew

" points " if they are in this condition.)

Check breaker point adjustment screws for tightness.

4. Make sure the nut securing the flywheel is tight and

that there is no free play of the flywheel.

5. By removing the flywheel examine the internal leads

for breaks and see they are all properly secured.

Make sure covered leads are not chafed and earthing.

6. If the insulation of the H.T. coil has broken down it

will show signs of charring on the outside but it is

unlikely that this will happen in normal use.

(Note: The ignition coil can only be tested with a high

voltage A.C. voltmeter.)

H.T. coil

Removal. First remove the laminated core complete, then

take off the coil. The core is held to the stator plate on three

studs. If a lighting coil is fitted as well, see that the thin wire

from it is not wrenched when removing the core. The H.T.

coil will slide off the core pole after straightening up the brass

tab seen at the top. Sometimes a fibre wedge may be found

between the coil and core but this is only used to ensure a tight

fit and may not be necessary if another coil is refitted. Due

to their individual manufacture, coil sizes vary slightly.

Replacement. The small brass tab protruding from the side

of the coil must face towards the flywheel being at the corner

nearest to the felt, cam lubricating pad. The two leads should

come Out from under the coil when it is on with the short lead

nearest the stator plate. This short lead is attached to the

core stud for earthing. The long lead is attached to the -

breaker arm spring block together with the condenser lead.

Bend the leads so that they do not foul the flywheel or cam.

It is most important to refit the red plastic band round the

coil and H.T. lead attachment and to see that it is in good

condition.

Lighting coil

Removal. This is the smaller coil and can be removed without

dismantling the core. First, remove the terminal from the

stator plate. Straighten the brass tab of the core and slide

the coil off.

Replacement. Replace in the same manner. Bend the brass

tab back over the coil after fitting to secure tight fit.

Condenser

A weak or faulty condenser can be detected by badly

burnt and pitted contacts or a continuous, intense blue spark

across the contacts when running. A very small white spark

across the points when running is normal.

Removal; - Release the condenser lead from the breaker arm

spring nylon block. Take out the clamp screw seen near the

top of the condenser and ease the condenser out The bottom

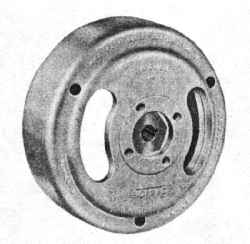

Series 90 Plain Flywheel

The Slots allow easy adjustment of "Points"

clamp is attached to the stator plate only. Replace in the

same manner.

Flywheel

This unit is robustly constructed and it is unlikely that

any faults will ever develop. They are scientifically balanced

before leaving the factory and made of a rust-proof metal.

Attachment of the flywheel to the crankshaft is by taper shaft

and key, locked with nut and shakeproof washer. The magnets

cast into the rim of the wheel are made of a special alloy and

will not de-magnetize in normal use. A keeper ring is not

necessary when dismantling.

Removal. Extractor tools are made and supplied by WIPAC

and should be used when removing the flywheel to save damage

to engine parts.

First, remove the flywheel nut and lock washer. Screw

back the main bolt of the extractor to its fullest travel, then

screw the smaller bolts into the flywheel. Continue tightening

the main bolt until the flywheel is freed. It is important to

use the small bolts supplied as they are designed to fit without

causing internal damage.

When replacing the flywheel make sure metalized dust

or small steel items have not been attracted onto the magnets.

Clean the flywheel inside and outside.

The finned-type flywheel must be removed to check the

contact breaker points as there are no slots.

The contact setting is cast on each type of SERIES

"NINETY" flywheel.

Flywheel extractors

Two types are available as there are two classes of flywheel.

One wheel has three holes drilled and tapped for an extractor

and the other has four holes. The THREE-hole extractor is

Part No.00586, price 5s. Od. The FOUR-hole extractor is

Part No.00494, price 5s. Od:

Contact breaker points

Gap adjustment. Turn the engine over until the breaker points

are fully open.

Test with feeler gauge between " points ". The correct

setting is cast on the flywheel but most " NINETY" magnetos

should be 0.0l8".

If the " points" require adjustment two screw heads will

be seen beside them. Slacken the large screw and carefully

turn the small screw, which is eccentric, until the correct gap

is obtained. Tighten large screw.

Removal. The complete contact set may be removed by

taking out the large-headed screw mentioned above and

undoing the two leads in the nylon block.

It is essential for the best performance to use only WIPAC

spare parts and where possible the name WIPAC is stamped

or cast on the parts. All "SERIES NINETY" magnetos

are guaranteed for six months from date of purchase and should

any fault develop within this time, return it complete to a WIPAC

agent or send it direct to the WIPAC GROUP.