| Before beginning to thrash

make certain that the thrasher is running at the correct

speed and that the power unit has a pulley or flywheel of

the right diameter for the thrashing drum speed marked on

the machine. The position of all belts is given on the instruction card mounted on the side of the machine Check the speed of the shoes by the method illustrated on the instruction card mounted on the side of the machine One of the causes of bad thrashing is the incorrect speed of the drum Never begin feeding until the drum has attained its full speed Feed as regularly as possible |

In feeding spread the sheaf

evenly over the whole width of the drum. While thrashing, examine all bearings occasionally to detect any heating or knocking, which should be remedied at once. Keep all nuts and bolts screwed up tightly, particularly those securing the drum beaters and beds(or drum pegs) Keep the road wheels and axles well greased Keep all sieves and shaker tops clean and free at all times When finishing the thrashing operations, and the raking etc., are being swept into the drum, great care should be taken that nothing passes into the drum likely to cause any damage to the machine. |

|

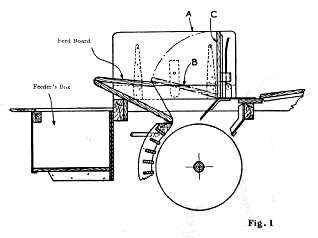

The Guard Boards at " A " are sent loose when the machine is despatched from the Works, and must be fixed in position at each end of the drum as shown

The drum guard board in position " B " must not be raised to position " C " until necessary for feeding the machine. |

It is the duty of the feeder to lower the drum guard board to the closed position " B " immediately feeding stops, and also whenever he has occasion to leave the feeders's box. |

The attention of owners of thrashing machines is called to the necessity for ensuring that when a machine is working, the guards supplied are in place, and are being used. Serious accidents have from time to time happened to persons feeding the drum, owing to guards not being used, and owners have been involved in the payment of large sums for cormpensation to the injured workers.

|

All spindles except the corn elevator and corn screen are fitted with self aligning ball bearings, including the jog crank dip bearings |

The shaker dip bearings are each fitted with two ball bearings to give perfect stability to the shakers, |

|

LUBRICATION OF BALL BEARINGS. The best lubricant for this purpose is a good quality mineral grease without free acid or alkali; this class of grease is also perfectly suitable for general engineering purposes. |

When the machines leave our Works the bearings are provided with an ample supply of this lubricant. A little grease should be pumped into each housing once a week. |

|

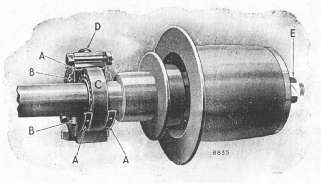

A-Distance Rings (Driving side only) for locating ball bearing in housing. B-Felt Dust Washer. C-Ball Bearing. Grease Lubricator. E-Nut securing inside bearing. |

|

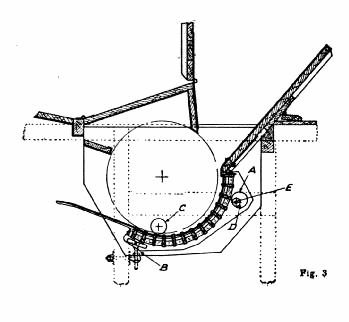

(2) Chock the hind wheels securely with the chain chocks and fix the fore wheels with the irons provided. There are two adjustments for the concave, at " A '' and'' B '' with sightholes at " C.'' The adjustment at" A '' is effected by turning the rods and cams " D " by means of a spanner applied to the square boss " E '' on the elevator side of the machine. The lower adjustment at " B " is made with eyebolts with screw adjustment as shown. Care should be taken that both sides of the lower adjustment are in line, i.e., in identical positions on the slotted adjustment brackets. For normal thrashing the distance between the drum beaters and concave bars should be approximately 5/16" at the bottom and 1¼" at the top. |

These distances must be varied to suit the different kinds and condition of crops to be thrashed. No attempt should be made to adjust the concave while the drum is in motion.

|

|

An adjustable straw check is provided, above the shakers, and this should be lowered if the straw is getting away too quickly without being |

properly shaken. If, however, the straw is remaining too long on the shakers, or if the drum has a tendency to wind, i.e., the straw tends to wrap around the drum, the straw check should be raised. |

|

The tailboard at " B is adjustable, and to obtain the best results it should be kept as low as possible, without losing grain with the chaff.

The first fan has adjustable shutters as shown at " A " and these should be regulated to suit the condition of thrashing. To reduce the fan blast the shutters should be closed. It is sometimes necessary to adjust the opening to the fan case by means of these shutters, differently on one side of the machine from the other.

FIRST DRESSING SIEVES.

Six grain sieves are provided, two seed sieves, and one blank plate and a chaff sieve.

|

When thrashing oats the seed sieve in the bottom of shoe should be replaced by the blank plate. CORN ELEVATOR. The belt carrying the elevator buckets must be kept tight, and central in the trunks by the adjustment of the top bearings. When the grain leaves the corn elevator, it can be diverted to the second dresser direct or through the awner to the second dresser. To provide for these alternative deliveries of the grain, a valve is fitted at the discharge point of the corn elevator, operated by a handle on the outside of the elevator. After passing through the second dresser the grain can enter the rotary corn screen or be discharged direct to the sacks through the door provided in the bottom of the screen hopper. BARLEY AWNER. (See Fig. 6). The awner consists of bars aud knives as shown in the illustration, revolving in a cast iron conical barrel. The bars and knives can be adjusted as follows :- Bars-Slacken the nuts at " A " and adjust the position of the bars on the brackets " F ", which can also be moved in relation to the cast iron bossess " C.'' By these adjustments the clearance between the bars and the conical barrel can be varied. Further variation is possible by moving the awner complete along the spindle, after slackening the set screws " D.'' This adjustment also varies the clearance in the barrel. |

|

Knives. These are adjusted by slackening the securing nuts " B '' and setting the blades at the required angle of " lead." The angle " G '' shows the normal working lead, as set at our Works before delivery. To pass the grain through the awner at an increased rate, the knives should be set as shown by the angle " E "

At the outlet of the awner is an adjustable door by which the discharge of grain is regulated. If awns or chobs cannot be readily removed, the door should be closed sufficiently to ensure the grain is ready for the final dressing. SECOND DRESSING SHOE AND FAN. The following sieves are provided for the second dressing shoe :- No. 5 -- 3/16" Holes. No 10 --3/8" Holes No. 6 --1/4" ' ' ' No 13 --1/2" Holes No. 8 -- 5/16" ' ' ' No 16 --5/8" Holes These sieves should be used as follows:- Top Sieve Bot'Sieve For Wheat of ordinary size . . . . . . No. 8 No. 6For Rye . . . . . . . . . . . . . . . . . . . . No. 6 No. 5 For Barley . . . . . . . . . . . . . . . . . . No.10 No. 8 For Oats . . . . . . . . . . . . . . . . . . . No.16 No.13 For Seed smaller than Wheat. . . . .No. 6 No. 5 |

The second fan is fitted with adjustable wind shutters which should be adjusted as with the first fan. Do not open these wide enough to prevent grain from flowing to the screen and bags.

ADJUSTABLE ROTARY CORN SCREEN.

The rotary corn screen separates the grain into three grades, the sizes of which are determined by the adjustment of the wires in the screen. When adjusting the screen, care must be taken to see that it is thoroughly clean, before the wires are set closer, or the wires may get bent and the screen strained.

BROKEN GRAIN.

If broken grain is found as it enters the corn elevator from the lower shoe, examine the setting of the concave and check the speed of the drum.

|

|

INSTRUCTIONS FOR THRASHING RAPE.

When it is desired to thrash rape, the bolts which secure the beaters should be removed and replaced by special peg bolts. The concave must be set back as far as possible and the instructions below followed :-- DRUM MOUTH. Bolt the plain sheet iron plate on the inner face at the top of the concave, and insert fine sieves in the upper and lower shoes. CAVINGS RIDDLE. An extra iron cavings riddle, with 3/8"holes is required for the jog-shoe. This must be fixed in place of the ordinary cavings riddle, care being taken to place the plank part of the riddle at the drum or back end of the shoe. SECOND DRESSING SHOE. An extra sieve with 5/32" holes is required for the second dressing shoe, and must be fixed in place of the usual sieve in the bottom groove, while the usual sieve with 3/16" holes should be fixed in the top groove. CONCAVE. Set the concave as for thrashing wheat, that is to say, about 5/16" from the drum beaters at the bottom, and about 1 1/4" at the top, al though this must , of course be varied to suit the nature and conditions of the crop to be thrashed. Tilt the feed board so that the rape-straw may be easily got into the mouth of the drum. Feed bolting, that is to say, parallel to the drum as far as possible. INSTRUCTIONS FOR THRASHING LINSEED. Feed the drum from the opposite side--not the usual feeder's box; also open the sheaves as much as possible while feeding. |

CONCAVE Set the concave about 1/8" from the drum beaters at the bottom and 1/2" at the top, although of course this must be varied to suit the nature and condition of the crop to be thrashed. CAVING RIDDLE. An extra wood caving riddle with 7/16" holes is required for the jog-shoe; this is to be fixed in place of the ordinary caving-riddle. FIRST DRESSING SHOE. Use one of the ordinary chob-sieves supplied with the machine, selecting a size that will just allow the unthrashed bulbs to pass through the holes with the seed, so that the bulbs may pass on and be broken up in the awner or chobber. SECOND DRESSING SHOE. Use the ordinary fine sieves supplied with the machine. ROTARY. CORN SCREEN. Set the screen so that only small round rape-seed will pass between the wires in the first half of the screen; the best linseed will then escape between the wires in the second half of the screen, while the bulbs, stones and any larger substances will pass out of the screen and be delivered out of the usual spouts for good corn. FOR THRASHING PEAS. The only accessory required is a plain sheet-iron concave plate for the drum. SPECIAL EQUIPMENT. The foregoing instructions cover seed thrashing under normal conditions, but where the crop and conditions demand special treatment, any necessary additional equipment can be supplied on application. |